Technology Summary:

RepelMAGICTM technology is a proprietary approach for preparation of multi-component mixtures containing optimized variety of hydrophobic- and/or oil-repellent molecular components. It offers great flexibility for water- and oil-repellant mixtures preparation in achieving highly efficient repellant properties – for specific surface applications and for the preparation of other subsequent types of repellent surfacing products such as paints, sealing agents, textiles, electronics, medical/surgical devices, solar cells, sport/occupational/military wear and else. The superior water-repellent properties are completely different from the properties of waterproofing that prevent water from permeating – the ultrathin nanolayers create molecular environment that exhibits repellent forces toward water- and/or oil compounds thereby allowing the existence of porous surfaces that are, nevertheless, permeability-protected.

The RepelMAGICTM technology supports the formation of 2- and 3-dimensional ultra-thin (nano-) layers which can interact chemically with the surfaces applied onto as well as with any other combinatorial mixtures thereby creating permanently-bounded repellent features – significantly outperforming (by 1000-fold) any of the existing similar products and suitable for virtually any-material applications. It allows for the implementation of any kind of additive substances and materials by the encapsulation binding properties of the surfacing layers formed – instantly upon application at ambient temperatures. The particular variation in concentrations (molar ratios) of the chosen-upon-design ingredients allows for best flexibility and optimization of the resulted nanolayer formation, as desired by specific application’s. These properties-upon-design are achieved by taking into account the molecular reactions’ variations as dependent upon the molar ratios of the mixed components.

Regon Technologies develops proprietary films and collaborates with companies to formulate custom coatings or reformulate existing coatings to add new properties. The core competencies needed to accomplish this include expertise in nanoparticle mixtures selection; functionalization coupled with coating formulation; technology in the areas of siloxanes, acrylics and urethanes on substrates such as glass, plastic, textiles and others; expertise in surface chemistry and physics; and knowledge of application development. Regon Technologies’s thin film coatings products may have one or more of the following functional properties using our nanotechnology and nanoparticle know-how.

Technological Advances:

• Unlimited options for products customization and properties optimization upon customers request.

• Instantly immediate layer formation – within 1-3 seconds.

• Ambient temperature application – within the range of -50ºC to +200ºC.

• Wide area of applicability – in practically all types of industries, materials and devices.

• Layer thickness design and chemical-reactivity properties design upon request.

• Layer strength design and repellency level design upon request.

• Encapsulation capabilities for attaching additional properties and materials with superior retention levels.

• Design and maintenance of certain optical properties based on fiber-optical effects.

Surfacing Properties:

Compositions are not soluble in water, thereby possessing maximum strength and binding properties

Surface binding is achieved by strong and permanent chemical bonds that can be disrupted only by mechanical forces.

The prepared surfaces are brilliantly shine but with reduced glare due to microfiber channeling effects reducing the light diffraction.

The deposition process results in disinfected surfaces due to the release of disinfecting chemical by-products and the microorganism entrapment by the formed nanolayer.

The secondary surfacing agents can be applied over virtually all primary surface treatments because they can penetrate the materials and the resulted strong chemical bonding entraps permanently the entire surfacing content.

Areas of Application:

The super water-repellent surfacing are expected to contribute to higher performance and durability, while maintaining the attractiveness of products

• Entire Household: Kitchen surfaces, floors, bathrooms, windows.

• Auto industry: These breakthrough coatings demonstrates superior effectiveness in preventing adhesion of snow, ice, and other substances besides water.

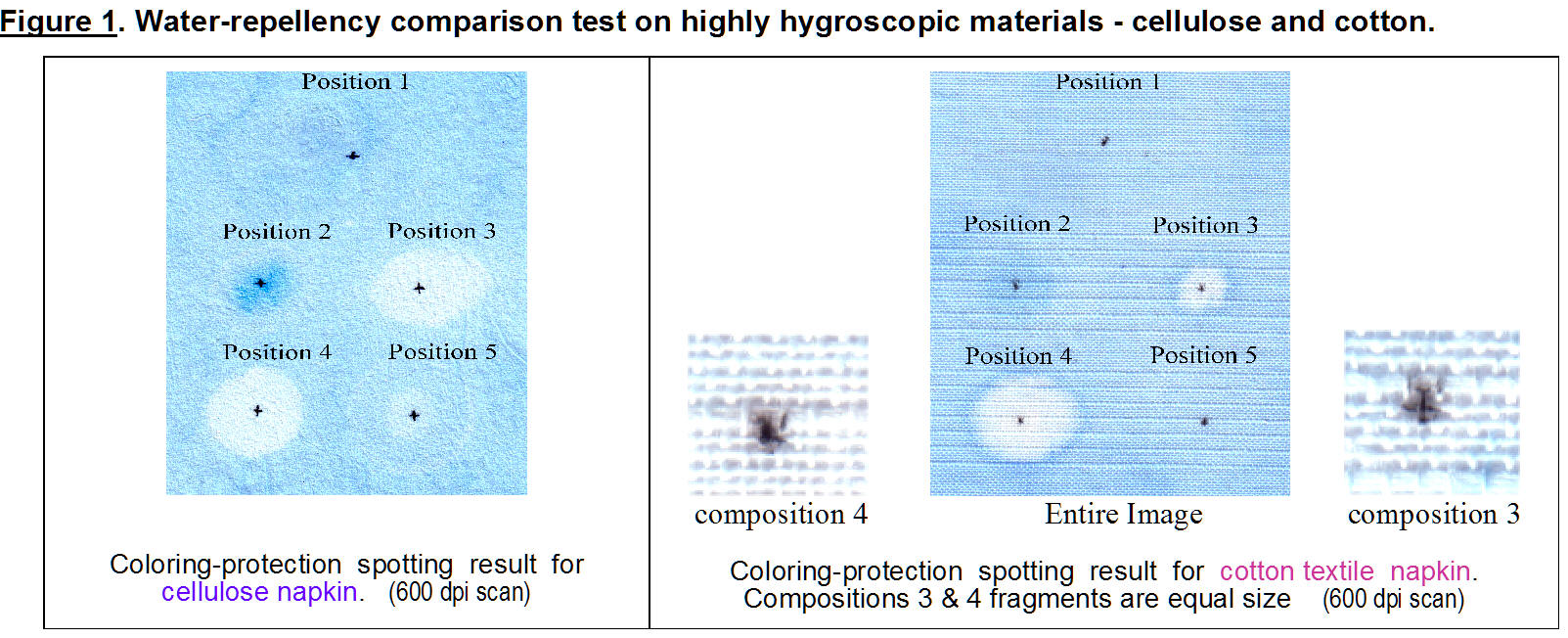

• Construction materials industries: bricks, stones, joint materials & compounds, concrete, terra cotta, porous masonry, mortar and more. Protects smooth architectural block from scuffs, scrapes, soil and stain penetration. Exclusively recommended for life-lasting surface protection of natural stone architectural appliances, especially – marble.

• Paint producing industries: allows for revolutionary level of repellency and optical properties (glare).

• Wood materials industries: brings life-lasting water (oil)-repellency and superior impregnation level.

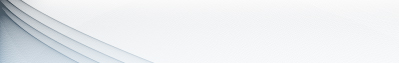

• Textile industries: for preparing breathable laminates, synthetic fabrics, leather, paper, jackets, bibs, rain gear, hats. The nanolayers binds to the fabrics creating the most durable water repellent finish available.

• Aircraft industries: brings new level of water- and ice protection combined with increased aerodynamics.

• Medical industry: brings repellency and instant surface sterilization to any surfaces cured.

• Optical industry: lens care for eyeglasses, sunglasses, goggles, cameras, scopes and any type of lenses and optical devices.

• Microelectronic industry: allows for 3D printing on the micro- and nanometer scale devices, objects and features; for insulation of communications equipment, allows for designing and manufacturing electronic transfer features.

|