NanoFIXTM technology allows for preparation of variable compositions of multi-component derivatization mixtures, multi-molecular compounds and other molecular components with demonstrating particular derivatization-, chemical-, repellant- and optical properties. It offers superior design flexibility in achieving extreme surface-attachment durability, outstanding chemical reactivity toward highly specific chemical groups or desirably universal specificity, chosen degree of water-repellency and other physical, and chemical properties for long-lasting (permanent) bonding. The technology opens a wide avenue for specific surface applications for preparation, attachment and impregnation of compositions used in biological, medical, mechanical and industrial devices, sensors or applications. The NanoFIXTM technology is intended for derivatization of surfaces with chemically-reactive groups for the attachment of biomolecules, pharmaceutical agents and/or other components, for manufacturing micro-devices, serving for detection, energy-delivering and energy-transferring purposes, and for microencapsulation/impregnation of small objects of biological and/or mechanical nature by the means of nano layers and covalent bonds formation.

Technological Advances:

· Great nanolayer design flexibility upon desirable physico-chemical parameters – achieved by varying the type-, the number, and the molecular proportions of the combined monomer compounds within the solutions.

· Superior chemical bonding.

· Exceptional durability.

· Very high chemical resistance and bio-tolerance.

· Universal applicability – attachment to all types of surfaces.

· Extremely fast performance at wide temperature range.

· Repellency- and optical properties upon design.

· Capability for electro-chemical and electrical interface- and inter-compound fabrications.

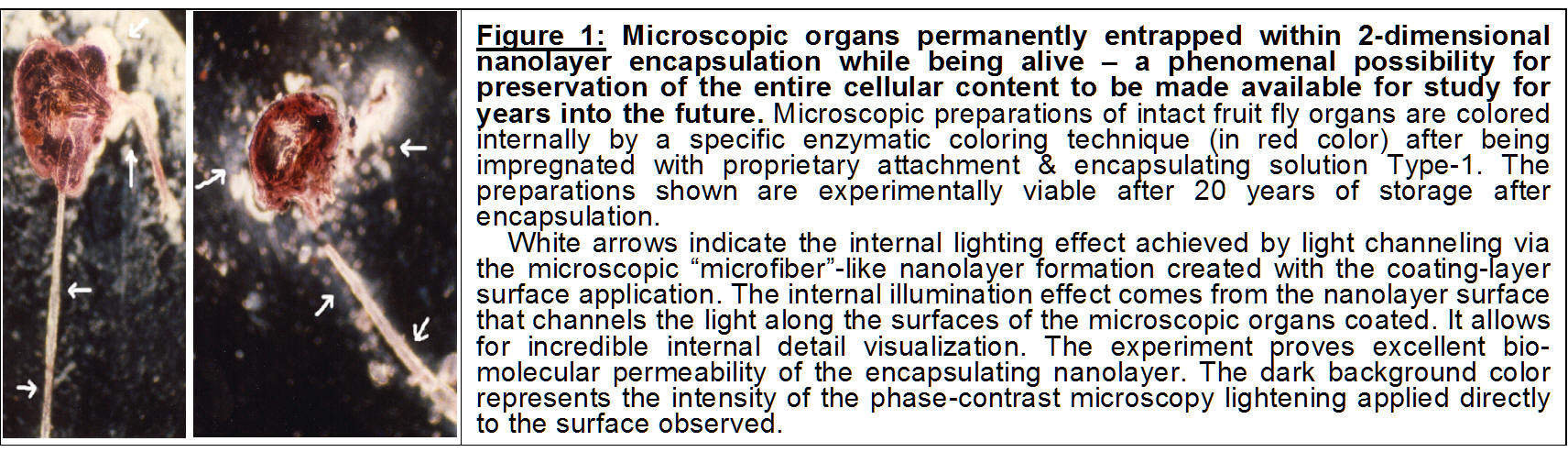

· Nanolayer permeability for large-size (bio-)molecules.

· Support for both photo-optical and electron transfer.

· Support for photo- and cloaking optical applications.

Areas of Application:

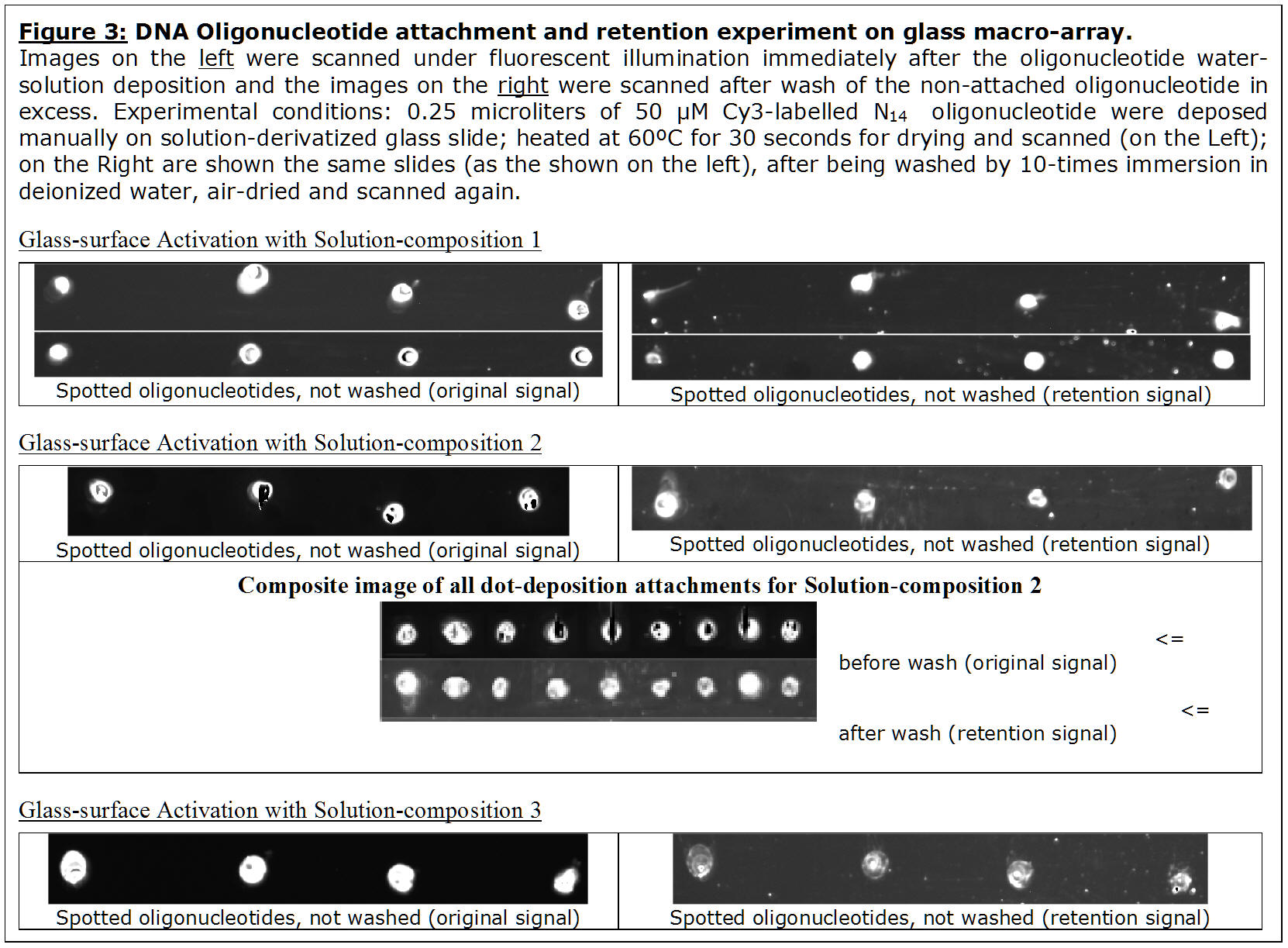

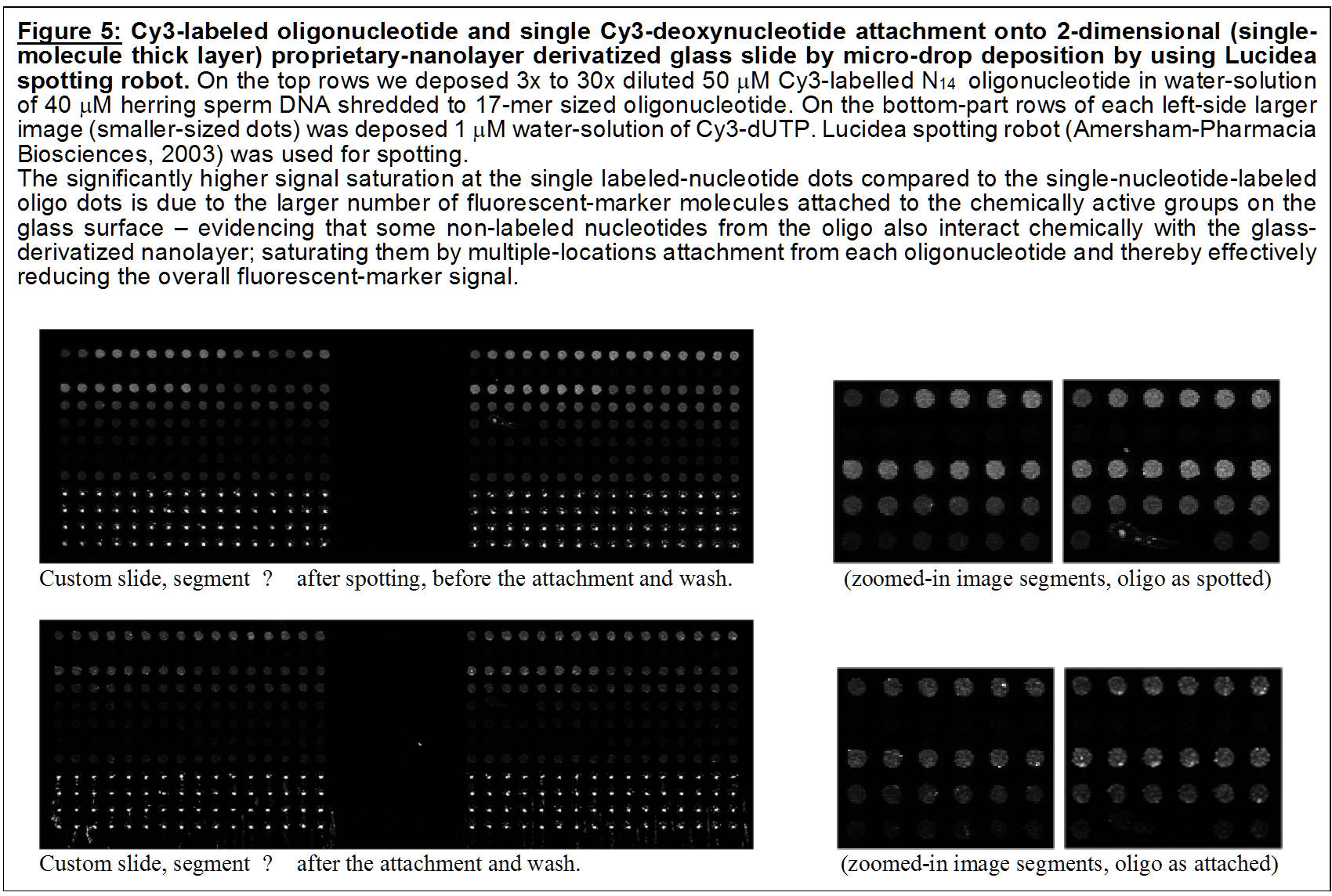

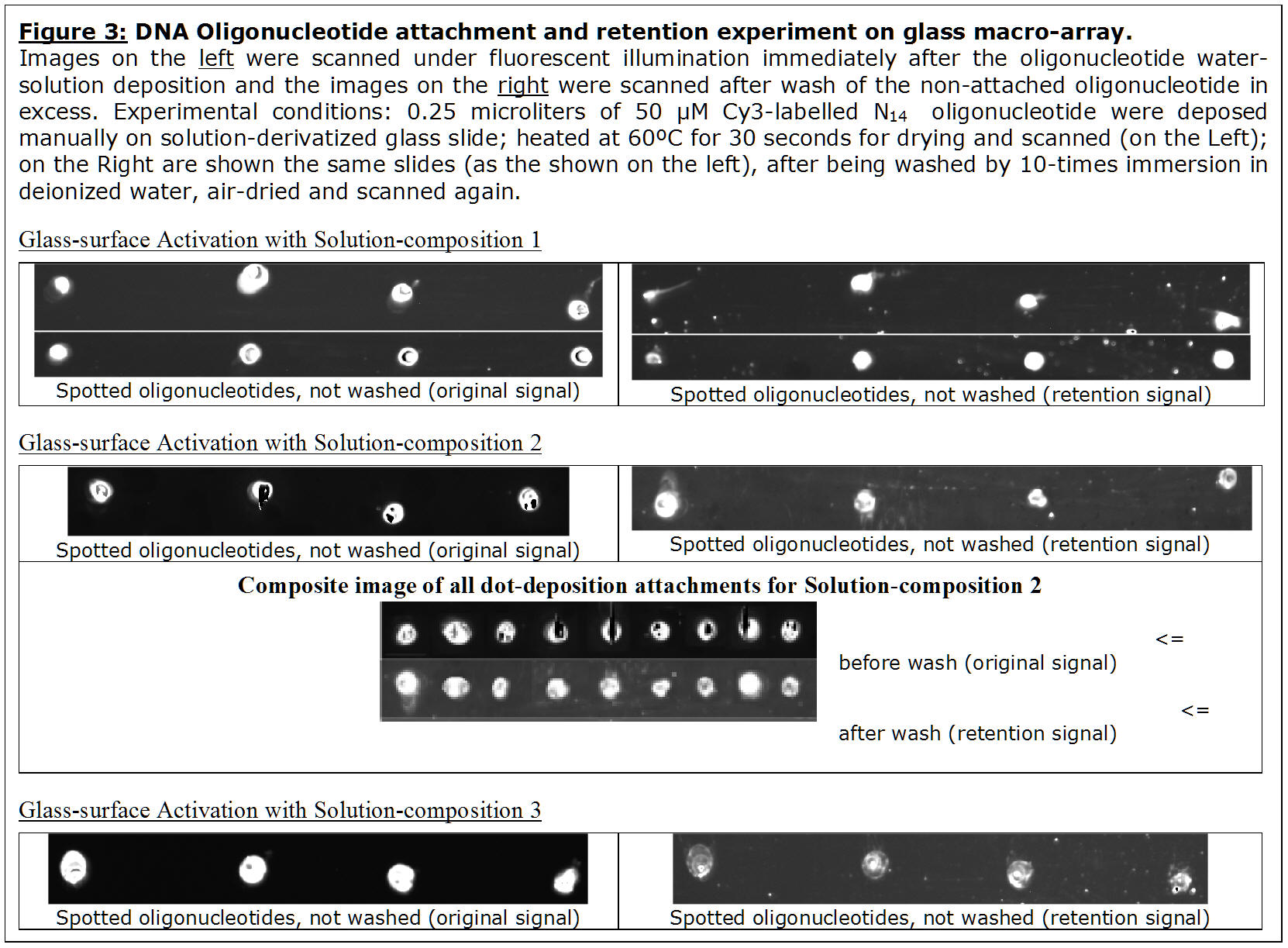

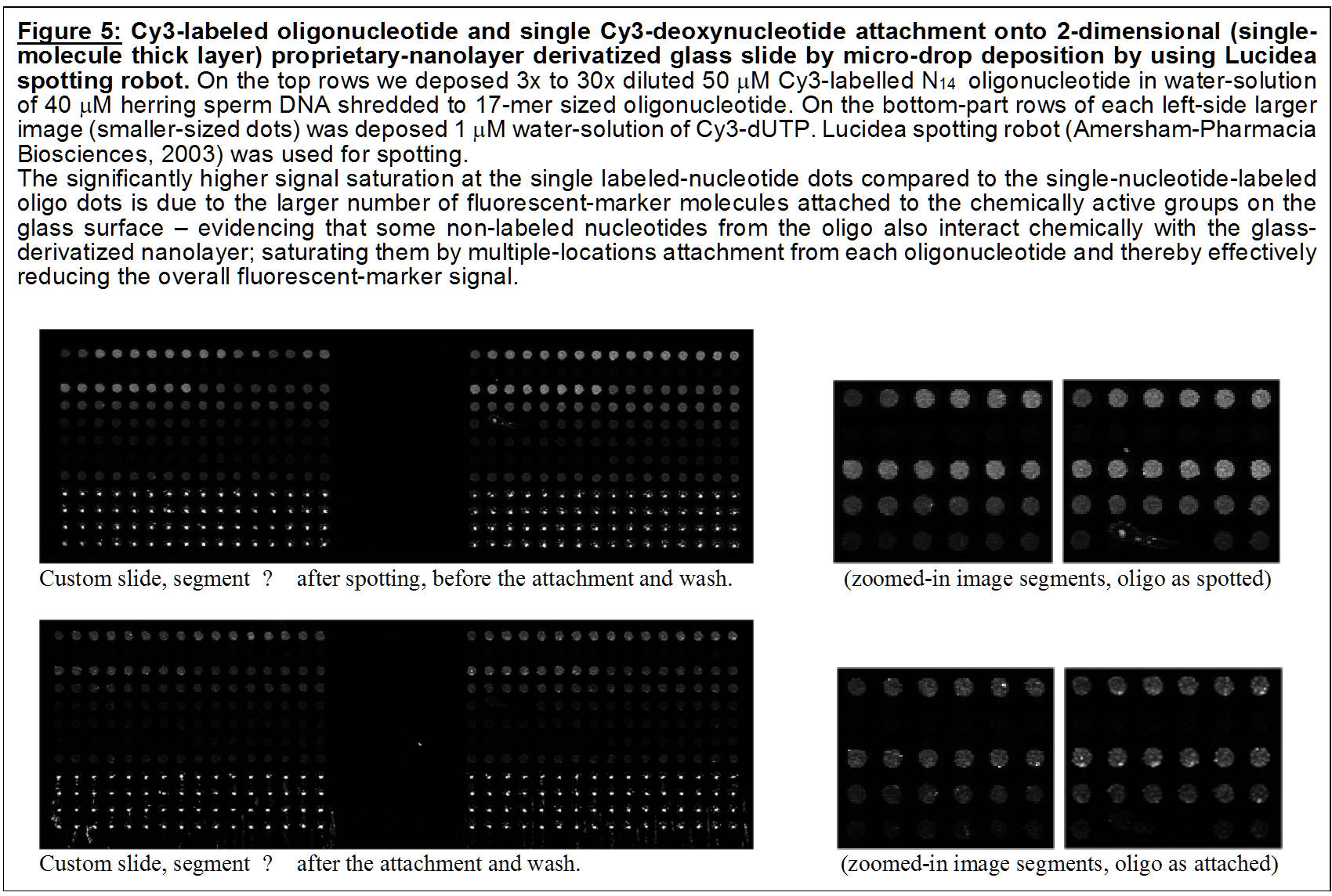

· Protein-, DNA/RNA-, DNA-RNA-Protein microarrays – combined or not with genetic, electro-chemical or optical sensors for both single-step or continuous monitoring.

· Pharmacological microarrays.

· Tissue- and cell attachments, arrays, fabrications and interface devices.

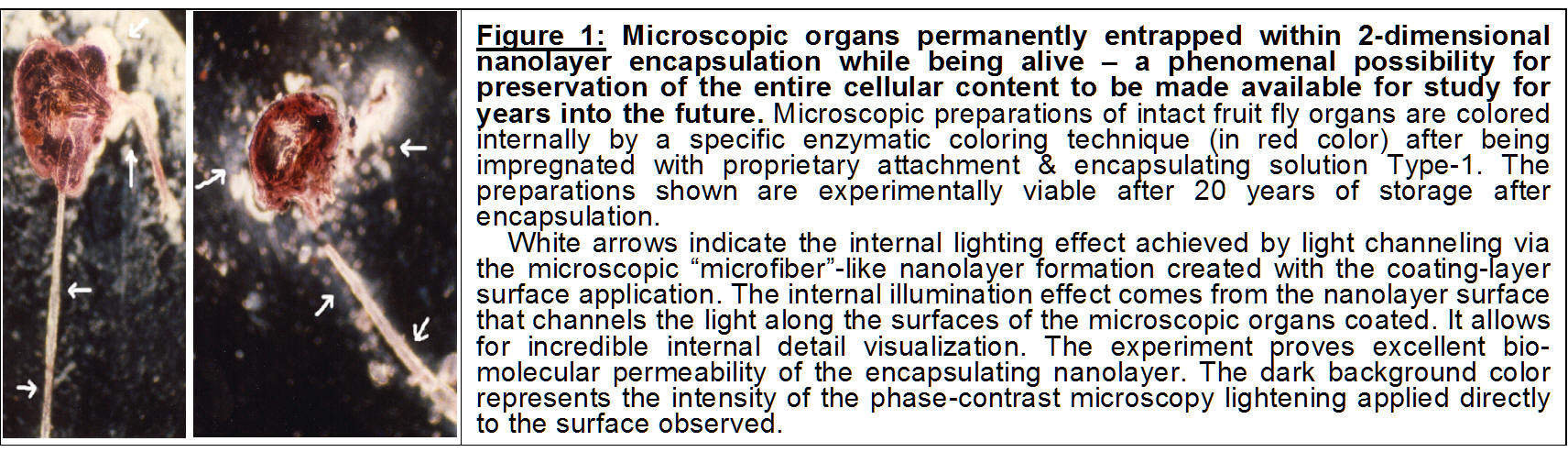

· Artificial tissue and organ fabrication via encapsulation – very high flexibility in nanolayer thickness (3D) design and micro-pore size design.

· Bio-medical engineering interface devices – attachment to cells and tissues.

· Microfluidics devices fabrication, detection sensors and biosensors.

· Micro-molding and 3D micro-printing fabrications with flexible micro- and macro-encapsulation of a variety of components simultaneously and repetitively. allows for 3D printing on the micro- and nanometer scale devices, objects and features; allows for micro-fabrication of devices via micro-patterning and micro-molding surfaces

· Nano- and micro-encapsulation of pharmaceutical and bio-pharmaceutical compounds and micro-fabrication of delivery vehicles.

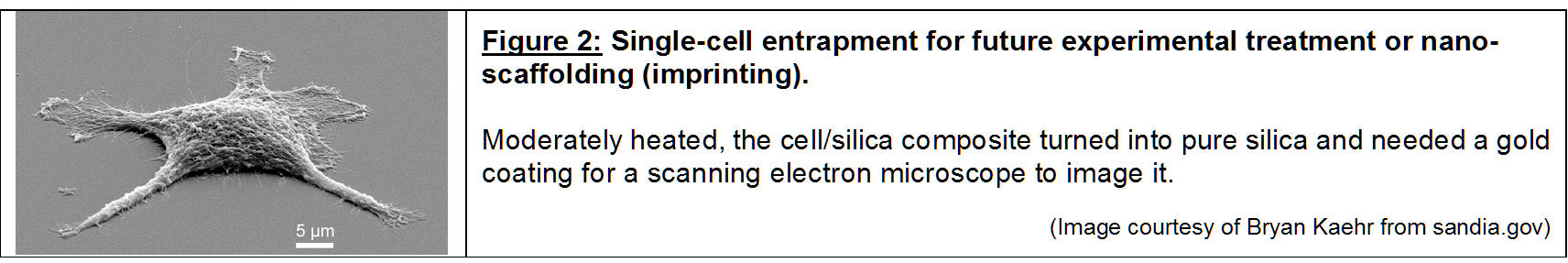

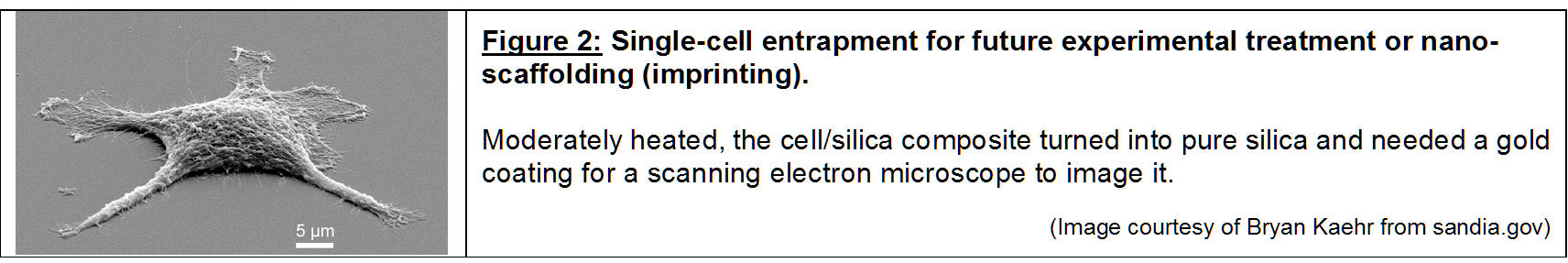

· Biomedicine, Bio-scaffolding and bio-impregnation – cell and tissue arrest. Capability for design of novel treatment- and surgical approaches by implementing cancer arrest or artificial temporary (or permanent) implanted bio-structures cells producing bio-molecular supplements in vivo. Protein- and cellular entrapment devices for bio-detection and diagnosis.

Test-experiments Examples:

|